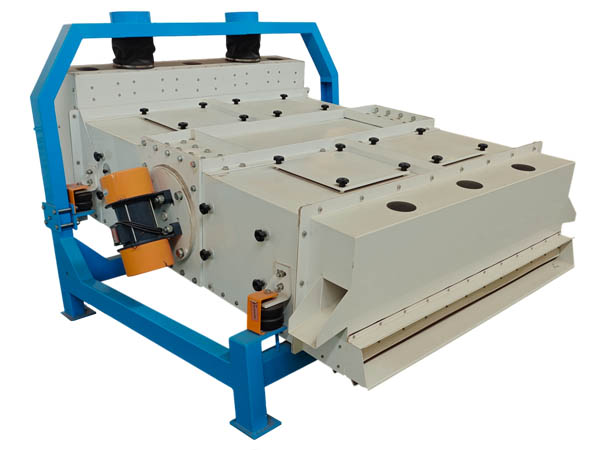

High-Capacity Vibrating Screen for Oilseed Pretreatment

KMEC’s advanced vibrating screens are designed for precision cleaning of oilseeds (soybean, sunflower, canola, cottonseed) and grains. As a critical seed cleaning machine in oil mill pretreatment, our ISO-certified separators achieve 99% contaminant removal through customizable screen configurations, significantly improving press efficiency and final oil quality.

Why choose KMEC’s oilseed vibratory separators?

- Double-deck screen technology – Removes both large impurities (stalks, stones) and small impurities (dust, sand) in one pass

- Customized screen sizes – Adjustable mesh configurations (0.5-10mm adjustable holes) for over 20 oilseed types

- Energy efficient design – 30% lower power consumption compared to conventional models (1.5-3kW motor option)

- High throughput – Handles 2-15 tons/hour depending on seed type and impurity loads

- Low noise operation – <75dB noise level, providing a worker friendly environment

Vibrating Separator Technical Data

| Type | TQLE100*100 | TQLE100*150 | TQLE150*150 | TQLE150*200 | |

| Sieve Size W×L(cm) | 100*100 | 100*150 | 150*150 | 150*200 | |

| Capacity (t/d) | Pre-cleaning | 30 | 50 | 75 | 100 |

| Cleaning | 8 | 12 | 18 | 24 | |

| Sieve Inclination | Pre-cleaning | 6 | 9 | 9 | 12 |

| Cleaning | 6 | ||||

| Vibration Inclination | Pre-cleaning | 25 | |||

| Cleaning | 20 | ||||

| Vibration Amplitude(mm) | 5~5.5 | ||||

| Matched Power (kw) | 2×0.25 | 2×0.37 | 2×0.7 | 2×0.7 | |

| Motor Rotation (r/min) | 920 | ||||

| Weight (kg) | 420 | 520 | 630 | 650 | |

| Matched Aspiration Pressure(mmH2O) | 50 | ||||

| Matched air Volume(m3/min) | 52 | 80 | 110 | 135 | |

| Overall Dimensions L×W×H (mm) | 1640*1610*1455 | 2140*1610*1455 | 2140*2160*1455 | 2640*2160*1455 | |

Technical Advantages

1. Enhanced Oil Yield

- Reduces oil loss by 1.5-3% through effective impurity removal

- Improves pressing efficiency by ensuring uniform seed size distribution

2. Multi-Stage Cleaning Process

- Pre-Screening – Removes oversized debris via upper sieve layer

- Fine Filtration – Eliminates undersized particles through lower mesh

- Aspiration Option – Integrated air channel for lightweight husk removal (optional)

3. Industrial-Grade Construction

- Reinforced steel frame with anti-vibration mounts

- Quick-release sieve plates for <10-minute maintenance

- IP54 protection rating for dust resistance

Application-Specific Solutions

| Oilseed Type | Recommended Sieve Size | Throughput Capacity |

| Sunflower Seeds | 3.5-5mm | 8-12 T/H |

| Soybeans | 2.8-4mm | 10-15 T/H |

| Rapeseed | 1.2-2.5mm | 5-8 T/H |

Industry-Leading Performance Metrics

- 99% impurity removal rate (tested per ISO 658:2002)

- <0.5% residual impurity in cleaned seeds

- 20,000+ hours average lifespan with proper maintenance

Trusted by oil mill operators worldwide

“After installing the KMEC vibratory separator, our sunflower seed impurity rate reduction dropped from 6% to 0.3%, and daily oil production increased by 10%.” – Francis Mwamadi

FAQ section

Q: What maintenance does the seed cleaning machine require?

A: Monthly bearing lubrication and sieve inspection (3-minute video guide provided).

Q: Can it handle high moisture oilseeds?

A: Yes – ask about our anti-clogging sieve coating option (+15% moisture resistance).

Q: Do you offer trial runs on customer material?

A: Free factory trials are available – send a 50kg sample for performance verification.

As a leading Chinese manufacturer with 30+ years of specialized experience in oilseed processing systems, KMEC has successfully delivered 500+ vibrating screens and complete oil mill plants to clients across Europe, Africa, Southeast Asia, and South America. We are always at your service.

Leave a Reply