- Pretreatment Section of the Oil Mill Plant

- Pressing Section for Oil Mill Plant

- Solvent Extraction Plant

- Oil Refining Plant

- Filling Section of the Oil Mill Plant

- Oil Modification Plant

- Seed Processing Plant

- Small Oil Production Line

- oil press

- YZS-30 Sesame Oil Pressing Machine

- YZS-68 Soya Oil Press

- YZS-80 Canola Oil Press

- YZS-95 Sunflower Seed Oil Press

- YZS-100 Oil Expeller Press

- YZS-120 Oil Pressing Machinery

- YZS-130 Screw Oil Press

- YZS-160 Oil Seed Press

- YZS-80A Combined Oil Press

- YZS-95A Automatic Oil Press Machine

- YZS-100A Automatic Oil Expeller

- Steel Silo

- Face Mask

- Oil Production Process 5S Groundnut

- Physical Refining Process Of The Edible Oil Refining Machine

- Cottonseed Oil Processing Equipment

- Something About Sunflower Oil Extraction Machine

- Something About Soybean Oil Refining Machine

- Something About Edible Oil Solvent Extraction

- Rice Bran Oil Extraction Equipment

- Soybean Oil Refining Equipment

vegetable oil refining plant

KMEC engaged in designing, installing and exporting of a variety range of vegetable oil processing plants since 1990. We offer state of the art technique of vegetable oil refining. Our vegetable oil refining plant is designed highly efficient and we also support customized services according to the specific requirements of our clients.

Vegetable Oil Refining Plant

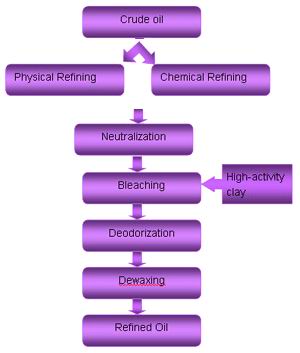

Crude oil is typically shipped for refining to establishments engaged in the production of edible vegetable oils, shortening, and margarine. Crude vegetable oils contain small amounts of naturally occurring materials such as proteinaceous material, free fatty acids, and phosphatides. Phosphatides are removed for lecithin recovery or to prepare the crude oil for export. The most common method of refining oil is by reacting it with an alkali solution which neutralizes the free fatty acids and reacts with the phosphatides. These reacted products and the proteinaceous materials are then removed by centrifuge. The oil is washed with water to remove residual soap, caused by saponification of small amounts of the triglycerides (oil). Color-producing substances within an oil(i. e., carotenoids, chlorophyll) are removed by a bleaching process, which employs the use of adsorbents such as acid-activated clays. Volatile components are removed by deodorization, which uses steam injection under a high vacuum and temperature. The refined oil is then filtered and stored until used or transported.

Merits of Vegetable Oil Refining

- Improve Vegetable and Edible Oil Quality

- Reduce Bleaching Clay Usage

- Conserve Nickel Catalyst

- Continuous Process Control

- Eliminate Human Interpretation Errors

- Exact Dosage of Used Supplements

- Timely Intervention at Process Changes

- Reduced Product Loss

- Higher Product Yields

We are always committed to provide the professional and advanced vegatble oil refining that are suitable for all kinds of oilseeds and for refining all kind of vegetable oils. Don't hesitate to contact us in the following form to learn more about our vegetable oil refining plant!