- Pretreatment Section of the Oil Mill Plant

- Pressing Section for Oil Mill Plant

- Solvent Extraction Plant

- Oil Refining Plant

- Filling Section of the Oil Mill Plant

- Oil Modification Plant

- Seed Processing Plant

- Small Oil Production Line

- oil press

- YZS-30 Sesame Oil Pressing Machine

- YZS-68 Soya Oil Press

- YZS-80 Canola Oil Press

- YZS-95 Sunflower Seed Oil Press

- YZS-100 Oil Expeller Press

- YZS-120 Oil Pressing Machinery

- YZS-130 Screw Oil Press

- YZS-160 Oil Seed Press

- YZS-80A Combined Oil Press

- YZS-95A Automatic Oil Press Machine

- YZS-100A Automatic Oil Expeller

- Steel Silo

- Face Mask

- Oil Production Process 5S Groundnut

- Physical Refining Process Of The Edible Oil Refining Machine

- Cottonseed Oil Processing Equipment

- Something About Sunflower Oil Extraction Machine

- Something About Soybean Oil Refining Machine

- Something About Edible Oil Solvent Extraction

- Rice Bran Oil Extraction Equipment

- Soybean Oil Refining Equipment

palm oil production

Palm oil and palm kernel oil is an important and versatile vegetable oil which is used as a raw material for both food and non-food industries. Palm oil production, however, is more and more popular across the world especially south east countries.

Vegetable oil production around the world totals over 144 million tonnes per year, of which over 47 million tonnes is palm oil. Along with soy oil, palm oil makes up 60% of world production. Palm oil can also be used in animal feedstuffs and as a bio fuel.

Palm Oil Production

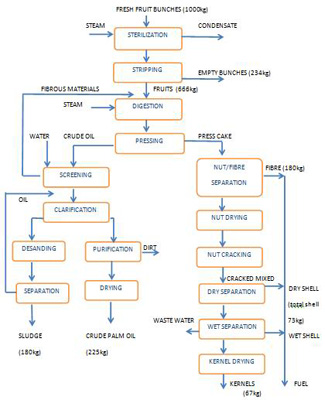

Palm oil production is quite a complicated process. First of all, palm kernel should be cleaned and seperated into small pieces. The palm oil has to be extracted and this requires the use of a system that is familiar to process plant engineers. It firstly involves separating a grading process where the good fruits are separated from the bad (which are then discarded) since they are lower quality. The good fruits are then placed in a large conveyer system which leads to a splitter which is true to it's name because it literally splits the palm fruits into smaller pieces.

The split fruit or kernels is then carried by a conveyer system and it falls into large cages which are placed in a sterilizer to be heated at a high pressure in a similar way to a familiar steam cooker. The cages containing the sterilized fruits are then taken by a rail carriage transporter to be emptied using a tipper and conveyed to a rotating threshing drum to separate the fruit from the husks and to go through screw conveyers to enter Digesters and then a presser will press the oil out or rather the CPO (crude palm oil) and the oil will eventually end up in a clarifier and then be dried using a Vacuum Type Oil Dryer to minimize the water content in the palm oil.

Nevertheless you may never have heard of palm oil since it’s rarely listed as an ingredient on product labels, with the term ‘vegetable oil’ often being used instead. Anytime you are interested in palm oil production, write to us!