- Pretreatment Section of the Oil Mill Plant

- Pressing Section for Oil Mill Plant

- Solvent Extraction Plant

- Oil Refining Plant

- Filling Section of the Oil Mill Plant

- Oil Modification Plant

- Seed Processing Plant

- Small Oil Production Line

- oil press

- YZS-30 Sesame Oil Pressing Machine

- YZS-68 Soya Oil Press

- YZS-80 Canola Oil Press

- YZS-95 Sunflower Seed Oil Press

- YZS-100 Oil Expeller Press

- YZS-120 Oil Pressing Machinery

- YZS-130 Screw Oil Press

- YZS-160 Oil Seed Press

- YZS-80A Combined Oil Press

- YZS-95A Automatic Oil Press Machine

- YZS-100A Automatic Oil Expeller

- Steel Silo

- Face Mask

- Oil Production Process 5S Groundnut

- Physical Refining Process Of The Edible Oil Refining Machine

- Cottonseed Oil Processing Equipment

- Something About Sunflower Oil Extraction Machine

- Something About Soybean Oil Refining Machine

- Something About Edible Oil Solvent Extraction

- Rice Bran Oil Extraction Equipment

- Soybean Oil Refining Equipment

Seed Processing Plant

Seed processing or oilseed processing can be defined as the methods or techniques used to obtain clean, high quality seeds. There are two schools of thought in the establishment of a work sequence for seed processing. They are batch processing and continuous flow processing.

Seed Processing Plant

Workshop of the Seed Processing Plant

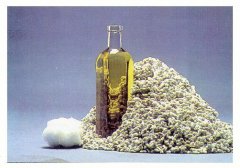

The seed processing plant is one of the most popular variations of oil mill plants in today's market. Seed processing is done based on one or more of the differing physical characteristics of the seeds, such as seed size, length, weight, shape, surface texture, color, affinity to liquid and electrical conductivity. In processing, the first phase consists of scalping, debearding, hulling and shelling to make the seed flow readily through the grader and cleaner (conditioning and pre-cleaning). The second phase includes the removal of inert material, weed seeds, other crops and broken seeds that are larger or smaller than the crop seed. In the final (separating and upgrading) phase, undesirable materials are separated from the seed.

With the constant rise in technology there are many machines available in the market which are used for the same purpose. These machines are fabricated and constructed to give them the utmost strength and sturdiness. These are used to clean, flake and cook all types of seeds such as sunflower seeds, castor seeds, mustard seeds, peanuts, soybeans, copra, palm seeds, rape seeds, linseeds, flax seeds, and many more. Some seeds vary from the others and need special machines to crack, cut, and clean them. Machines of all sorts are available to meet all these requirements. The machines available in today's market for the process of seed treatment are categorized as seed cleaners, seed flakers, seed crackers / breakers, hullers, copra cutters, decorticators / separators, destoners, hammer mills / disintegrators, boilers, seed cookers / heating kettles, seed elevators and seed conveyors. One of the main advantages of using these machines and equipment is that they save on labor. This in turn helps save time as well as increases the output of oil production. By making use of seed processing equipment, the oil that is extracted is also of the highest and purest quality as the machinery provides more accurate and precise results.

Oilseed Processing

Batch processing provides the flexibility to vary the type and sequence of seed processing steps to meet the individual needs of different species of seeds. People can monitor the seed at each step in the solvent extraction plant process. Adjustment and recleaning are easily accomplished. Equipment may be changed and updated as appropriate. The batch system is generally favored especially for smaller oilseeds.

In a continuous flow system, however, cones and seeds move though an interconnected sequence of processing steps. Thus, fewer people will be needed in the seed cleaning process. If there is any equipment failure, the entire processing system will be shut down. Because of the required conveying equipment, the possibility for seedlot contamination is increased. It is also much more difficult to determine the specific cause of seed damage in a continuous flow system. The continuous flow system is more common in extraction where large oilseeds are being processed.