Rice Bran Oil Extraction Process

Rice bran usually has 17% oil content by weight. The refined rice bran oil after a series of rice bran oil extraction process, the oil content weighs only 12% of the total raw material.

Rice Bran Oil Extraction Process

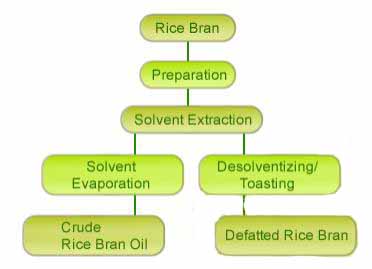

Rice bran oil extraction process begins with rice bran preparation. First of all, rice bran is screened, then be heated by steam at temperature higher than 100 degrees Celsius to stop Lipase hydrolysis in rice bran prior to extraction process.

Then rice bran solvent extraction plant will be used to extract oils from rice bran. Advanced extracting technology and techniques were developed with technical assistance in order to come up with crude rice bran oil that is high in vitamin E and oryzanol. The crude rice bran oil is forwarded to the refining process for purifying and packing.

Advantages of Rice Bran Oil

Compare to other commercial vegetable oil, rice bran Oil container more Phytosterol ( Plant Sterols ) and unique Gamma-Oryzanol that have potential in reducing LDL Cholesterol.Refined rice bran oil is a kind of high-quality cooking oil, whereas crude palm oil has been used for soap manufacturer and for the production of industrial fatty acids. In humans, ricebran oil is reported to improve plasma lipid and lipoprotein profiles.

With rich experience and advanced rice bran oil mill machinery technology in this field, KMEC is your reliable rice bran oil plant manufacturer and supplier. The output rate of rice bran oil mill machinery is between 8-11% and the capacity is from 5t to 100t per day.

We supply professional rice bran oil extraction process to all of our customers. Our clients are also very satisfied with our rice bran oil extraction process and they also expect next cooperation. If you prefer to know more info about the detailed rice bran oil extraction process, please don't hesitate to contact us, we are always at your service!