Fatty Acid Distillation

Fatty Acid industry is associated with production of fatty acids and glycerine. Both vegetable oils & animal fats are being used as feedstock for fatty acids / glycerine manufacturing. The fatty acids are manufactured as a distillate mixture or a pure fraction. Pure fractions can be obtained either from fractionation plant or by selectively choosing the feed-stock & carrying out straight distillation.

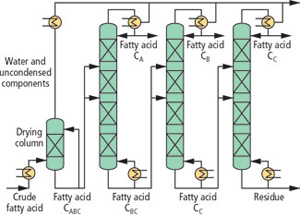

Fatty acids generated during Fat Splitting, or methyl esters from a transesterification process, are generally purified by distillation to separate the fatty acids into groups according to their chain lengths. Depending on the distribution of fatty acids or FAME and their intended uses, the distillation consists of a series of distillation columns that are designed to create specific cuts of fatty acids at a specific purity level. With such a wide range of boiling points for various fatty acids and the impurities (usually monoglycerides) in the feedstock, the process is usually tailored to remove a heavy cut (pitch) that contains very little fatty acid. The rest is often separated into a narrow range of fatty acids, but not so narrow as to only contain a single chain length. For example, a FAME produced from palm stearine may be separated into a high purity C:12 feedstock for MES applications and a high CFPP biodiesel product.

In order to separate components by degree of saturation, alternate methods of separation are often used because the degree of saturation does not change the boiling point of a fatty acid of a given chain length enough to be practical to separate by standard distillation. The fatty acid distillation is done under vacuum to achieve a reasonable boiling point for the fatty acid cuts. An antioxidant can also be added to the finished product.

Fatty Acid Distillation Plant

Fatty acids distillation plant is broadly divided into three main section. vis. de-gasification, pre-cut system and main distillation system. These main process section are supported for optimum cooling based on thermostatised water system.

The distillers are towers with structured packing to fractionate heavy and light boiling impurities and to ensure that the fatty acids are distilled at the lowest possible temperature. Squeezing of the residue is carried out in a separate distiller. Condensation can be carried out inside the tower over packing with cooling of an external pump around or outside the tower in shell and tubes condensers. In both cases heat is recovered generating low pressure steam. Canned pumps with falling film reboilers or centrifugal pumps with suppressed vaporisation reboilers are proposed according to the case.